Intelligent Stamping Dies

Background: The art and science of Sheet Metal Stamping has so far been driven by considerations of speed and simplicity. Presses have been regarded as a sturdy steel monster which could simply apply brutal force in one direction and produce higher strokes per minute; until electronics entered them and modern costly presses have started integrating elaborate Data Acquisition Functionality and PLC which could communicate on the net. However, most ERP and data repository systems so far have not got bilateral connectivity with Shop Floor Equipment monitoring and utilization.

Traditionally Cold Stamping Dies have been mostly deploying the principles of holding, guiding, mechanical cam actuation, clearances and material flow and somehow so far they have remained isolated from inclusion of technologies like Servo-hydraulics, Piezo Actuators, Electronic Sensors, and Telemetry

Given that cost of electronics has become much lesser than cost of Die and there is all pervading availability of hardware and software for Internet Communication and Data Acquisition; there is enough reason for these features to find application in Stamping Dies in near future.

Requirement:

- There are many variables in the forming process and need is felt for adaptive control within tool. Sheet Metal Assembly Lines have already started coming with adaptive control of Spot Welding gun electrode squeeze, welding current and counter for spots and number of assemblies made. Weld Lines of the future could have Light Radar or Optical digitizers for in-line Quality monitoring.

- Speed on Automated production Lines is so much that by the time a flaw may get noticed (if at all) already hundreds of faulty components/assemblies may get rolled out.

- In complex scenario of automotive OEM where many metal forming processes are outsourced, it becomes increasingly difficult to keep track and get credible data of tool use /abuse, quality trend and condition of suppliers’ Press.

Features to come:

- Electronic sensors which measure (in-line) quality, monitor process parameters and variability

- Actuators which adapt to variations and automatically take care of requirements where same tool might be used for different materials or even for producing variants of similar component.

- Internet of Things ( IOT ) Communicator to log the acquired data on Cloud.

- Mobile and Desktop based apps to show customized dashboard and trigger auto mailer/sms to concerned personnel.

Some Examples:

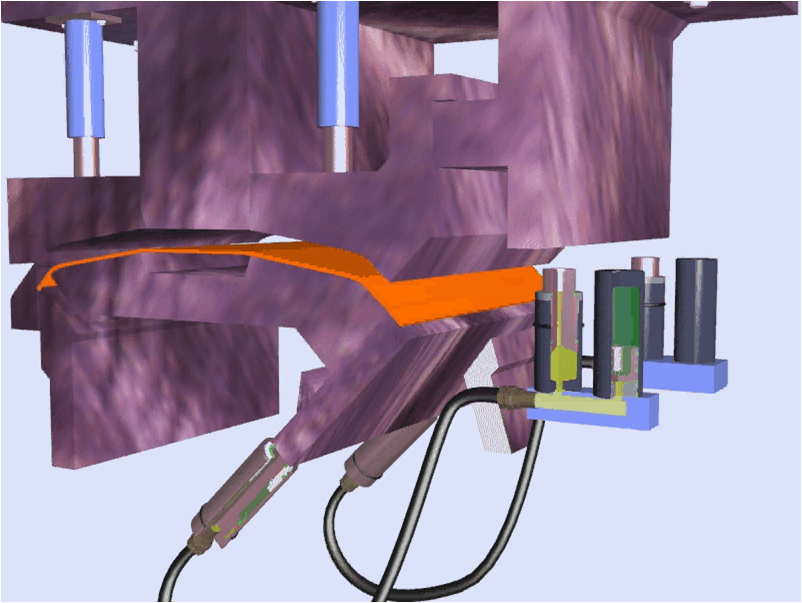

- Hydraulic CAMs are available, their use enables design of compact Dies since driver unit could be conveniently placed and offers possibility of multiple CAM actuations with control on sequence, speed and force. It could be readily integrated with Servo-hydraulic Control for adaptive control.

- Gas Springs are used to substitute use of Cushion pins, traditionally all similar Gas springs were being charged to same pressure / force and they were connected together in parallel with common inlet, so that if any Gas spring leaked all would drop out of function together avoiding damaging skewed force at the Die. Now Gas Springs come with wireless communication of pressure reading to a host computer so that the forces could be individually set and monitored dynamically; this offers simpler reversible option for Die proving and tryout.

- MATRICI Spain in its venture of High Tech Die ( HTD ) intends to offer following new integral service to its customers:

- Control the usage of the dies within the optimum conditions under which they were sensors that allow to check the main stoppage causes in real time owing to:

- Impaired Scrap sheds detection through sensor at Die

- Abnormal Kinematic detection through extensometer at Die

- Material splits detection by noise sensor

- Control and reduce the causes of production stoppage at the press lines by using designed:

- Measurement of Local and total stresses

- Production rate – Life Monitoring

- Control the usage of the dies within the optimum conditions under which they were sensors that allow to check the main stoppage causes in real time owing to:

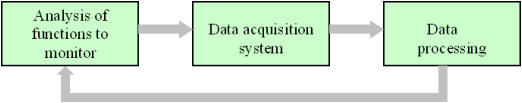

HTD considers the following stages:

And also proposes the following solution: