Mahindra & Mahindra Limited, Automotive Division – Mumbai

Name of company: MAHINDRA & MAHINDRA LIMITED, AUTOMOTIVE DIVISION

Address of the Plant / Site location: AKURLI ROAD, KANDIVLI-EAST, MUMBAI- 400101, MAHARASHTRA

Brief Description of the project.

Conserve to Preserve - A Step towards Carbon Neutrality by Adopting Green Manufacturing Process to Improve productivity, reduce product cost & enhance quality of life.

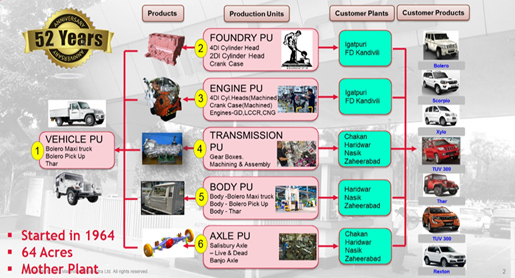

Mahindra AD Kandivali Plant: - Background

This plant was established in 1964, oldest amongst the Mahindra Manufacturing Plants. This plant is called mother plant as it supplies Aggregates like Axle/ Transmission Gear Boxes to other TCF Plants. This is the only integrated Manufactoruing plant ( From Captive Foundry to Vehicle Roll Down) located in High Wage island metrocity- Mumbai.

Plant area is 64 Acres and Employee strength is 4500+We have a Dream- To be amongst the Top 10 Global Automotive Brands. To Achieve this, we had started Journey in 2007 with Milestones in the form of Promise 2010, 2013, 2016, 2019 ,2022 and so on. Currently Promise 2019 is in force. Since, promise we have declared is to reduce Specific Caron and water Footprint by 15% as compared to FY16 Level. Sector specific Energy Management Policy and Plant Specific Water Management Policy are the guiding documents.

Climate change is a major challenge for developing countries like India that face large scale climate variability and are exposed to enhanced risks from climate change.

Drawing inspiration from above, our project is a A Step towards Carbon Neutrality by Adopting Green Manufacturing Process to Improve productivity, reduce product cost & enhance quality of life.

Trigger for the project. (10 Points)

Foundry is being considered as one of the most hazardous and dangerous process which consumes lots of natural resource. Team Foundry took a challenge to reduce the Natural resource consumption, Improve the Productivity and Reduce Conversion Cost.

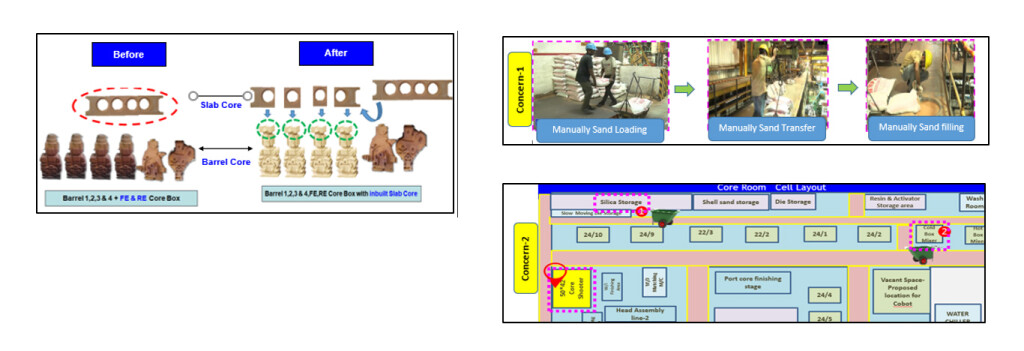

Concern-1: High Natural Resources Consumption

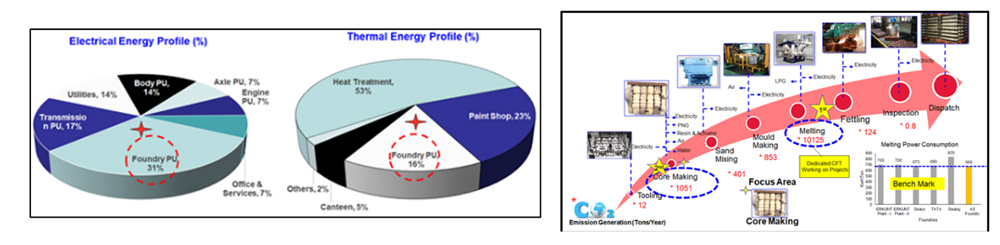

If we analyze the electrical & thermal consumption of the Kandivli plant, Foundry unit consumes 31% of the total power & 16% of total thermal energy.

Upon mapping the C02 profile cell wise melting contributes the highest due to presence of induction furnaces where a dedicated CFT is working under ENCON for its reduction. Core Room cell ranks second due to PNG heated core making machines, so the team took up the challenge to reduce it.

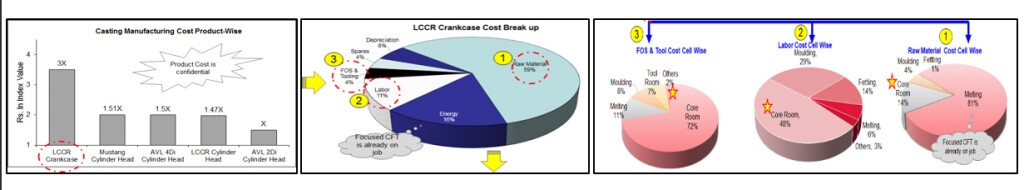

Concern-2: High Casting Manufacturing Cost

To retain the cost competitiveness in this VUCA world we plotted the casting wise product cost wherein LCCR Crankcase was highest which upon further bifurcation revealed that contribution of raw material (59%), labor (11%) & FOS – Tooling (4%). These costs were further plotted cell wise wherein Core Room cell was highest so reducing the overall cost of Core Room cell was targeted

Core Room Cost breakup of top three contributors where further analyzed & highest contributors were Raw material - Resin Coated sand, Labor – on 32 Series machine & FOS Tooling – PNG

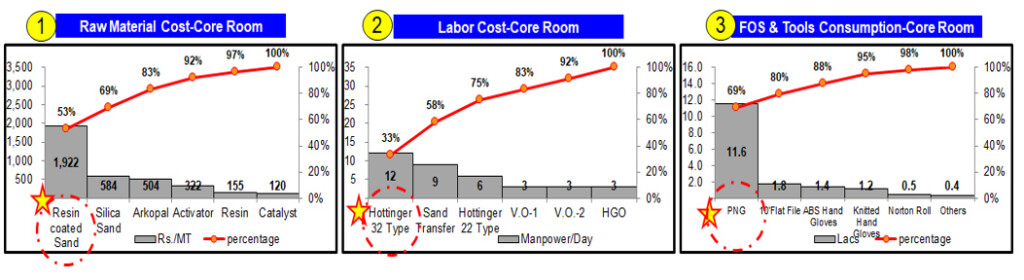

Concern-3: Less Crankcase Casting making capacity

To cater to the projected increase in crankcase casting demand, capacity dispatch mapping was done cell wise wherein the core room capacity had a gap of 3500 nos. Barrel 1&4 and Barrell 2&3 were having least capacity. Hence focus was on increasing its capacity.

To Manufacture one crankcase core assembly 7 varieties of core were required which were manufactured on 4 machines & its productivity was less due to high cycle time. To overcome it M&M Foundry started looking for Innovative and sustainable and Productivity project for moving towards Improving quality of life, improving business performance, making technology affordable and Green process to achieve sustainable business model, a positive step towards achieving an inclusive growth. Foundry Team did a process mapping of Core room and identified gas heating (High Cycle Time) is one of the influencing deterrent factors to aim our goal. Our team decided to think differently and create positive impact on our business with enhanced Productivity. The team challenged the conventional process of shell core process making and implemented cold box process for LCCR Crankcase barrel core making with changing the die design and thereby moving towards green manufacturing

Solution Generation & Innovation (20 Marks)

Core making process which required manual feeding of resin coated silica sandbags 300 Nos Per Day of 50 Kg each into a 38 years old machine in which dies were heated and maintained at 300 0C by using Process Natural Gas for heating .It was a nightmare for the machine operator to remove heated cores from the Die at 300 0C due to Process Limitation, it was consuming high quantity of natural resources which lead to generation of high amount of carbon dioxide and the Cycle time of machine was very high resulting into to low productivity. So, in a nutshell it was impacting the 3Ps i.e. People, Planet Profit

Action 2: Integration of slab core with barrel core

The team came up with an innovative way of integrating the slab core within the barrel core neck portion thereby eliminating the need of one variety of core

Hurlde c. Low sand supply capacity

Solution: Pneumatic sand transfer system

The existing sand requirement was 1.4 ton/hr. which was catered by manual sand transfer & addition to individual machines. As a result, time required for sand transfer was more & high fatigue. Also, the layout of machine & manual sand mixing operation made it more difficult.

The revised sand requirement to cater to increased demand was 1.9 ton/hr. which was 0.5 ton less than the existing capacity. The team has studied the process flow, operational requirements & with aim of improving the sand supply capacity pinned on a low-cost solution of pneumatic sand transfer system with auto sand mixing & dosing facility. This frugal solution gave an output of 2.4 ton/hr. therefore making it future ready for further capacity enhancement

Hurlde d. Manual Core Unloading

Solution: Pneumatic sand transfer system

For core unloading 80 kgs of core needed to be lifted manually around 160 times/shift which challenges the endurance of operators and classified as yellow stage under ergonomic SSES analysis.

The team started working on evaluating various options to improve quality of life of operators & reduce fatigue while reducing fatigue by exploring various frugal alternatives to the standard most sought out alternatives such robots. But due to high capex and space constraint the team developed a flexible core unloader thereby converting the stage to green as per SSES analysis

Hurlde e. Manual Data capturing

Solution: Industry 4.0 & IOT Real time data capturing

Traditionally all the data required to calculate productivity, quality, cost parameters was done manually which required high time

The team leveraged the concept of industry 4.0 & IoT for real time data capturing using smart sensors & thereby eliminating the manual activity

A Step towards Carbon Neutrality by Adopting Green Manufacturing Process

Results / Impact. (20 Marks)

Value Creation and Business Impact:

Benefits under PQCDSM:

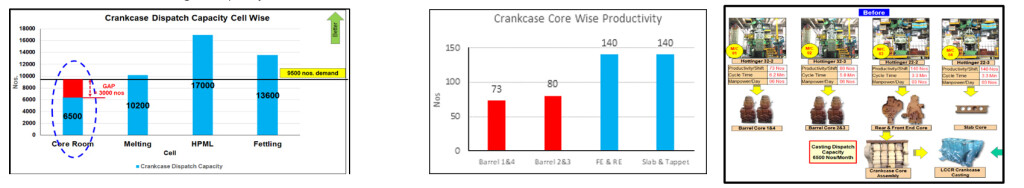

Productivity (P): -

- Crankcase Core making Productivity increased by 110% (from 80 Nos/shift to 168 Nos/shift)

- Work Content Reduction of 4.41 % at PU Level

Quality (Q): -

- Customer End rework due to Fins eliminated.

- Surface Finish of Casting improved which lead to delightful customer Experience

Cost (C): - Total Cost Saving-362 lakhs/Annum (YOY)

- Raw Material Cost Saving of Rs. 242.7 Lakhs/Annum.

- Electrical energy Cost Saving of Rs. 8.08 Lakhs/Annum

- PNG Cost Saving of Rs. 52.4 Lakhs/Annum

- Additives Consumption Cost Saving Rs. 46.7 Lakhs/Annum

- Manpower cost saving of 12.7 Lakhs/annum

Delivery(D): -

- LCCR Crankcase Dispatch capacity increased 6500 Nos/Month to 9750 Nos/Month

- Opportunity to generate new business

- Retaining existing cost competitiveness in the market

Safety(S):-

- Operator fatigue due to manual sand transfer eliminated

- SSES Yellow stages changed to Green Stages

Morale(M):-

- Delightful experience to stake holder

Environmental Impact ( 10 Marks)

- Carbon Footprint Reduced-581 Tons/Annum

- Electricity consumption reduced by 42%

- PNG Consumption reduced by 100%

- Raw Material Consumption reduced by 51%

Scope for Horizontal Development: (10 Marks)

Shared idea with following industries

Any other merits.(10 Marks)

a) Innovative & First time in industry solution of manufacturing 7 varieties of crankcase cores in a single machine. This unique system is applied for PATENT with patent registration no 2791/PAT/2019

b) This Project was rewarded as the best sustainability project in entire Mahindra & Mahindra sector for the year 2019 for its frugal first in industry solution to increase quality of life of operators & drive positive change in life of all stakeholders enabling them to RISE