Adler Mediequip Pvt Ltd

Project Title : Automation in Rasp Teeth Punching Process (Trial Implant)

Location

Name of company: ADLER MEDIEQUIP PVT LTD.,Address of the Plant / Site location: A-1, MIDC Sadawali – Devrukh, Tal Sangameshwar, Dist Ratnagiri

Product & Process:

Product - Rasp cum Trial Implant

Process – Teeth Punching operation

Objective:

To establish predictable and efficient teeth punching process for Rasp.

Summary

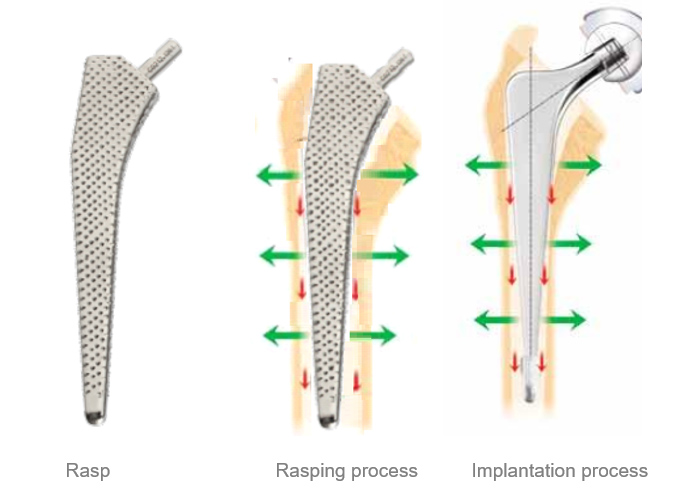

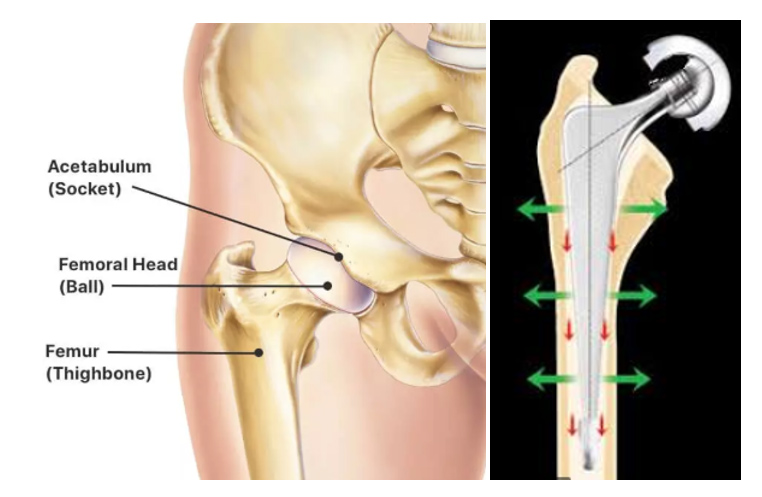

Rasp - It’s a trial implant for the femoral Hip replacement. Rasp to compress and compact cancellous bone without bone destruction in order to create an excellent cancellous bone cavity for the implant to fit correctly inside the bone.

Please refer the above images for the Rasp and Stem implant. For trial implant material is Medical grade stainless steel 17-4 PH and Implant Material is Titanium alloy / HNSS.

Rasping process is important for the Hip replacement surgery. Bone cavity is enlarged by using Rasp cum trial implant. The teeth are designed in such a way that the teeth would compact the cancellous region instead of bone cutting. It also helps to create correct size of stem to be implanted. Hence the teeth play the important role in success of the surgery. Uniform placement of teeth over dis similar surfaces & no 'Reverse Bite’ are some of the critical functional requirements.

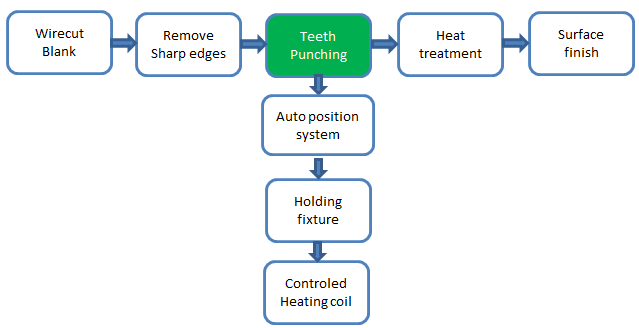

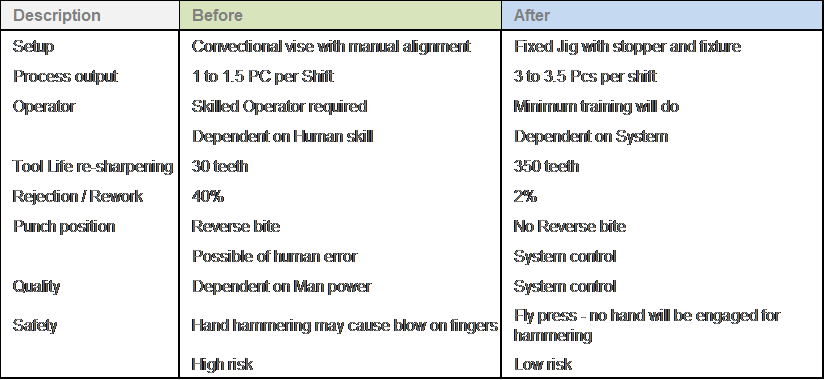

Teeth punching process is critical and important, below the list of challenges being faced by production every day;

- Manual punching operation & hence high skilled person required

- Unpredictability in terms of setup time & rework

- Repeatability & Quality issues due to fatigue

- Need annealing of parts before punching – high cost & high lead time

- Throughput issue (Lot of handling and to and fro process)

- Very low Output per shift 1 PC (Approx. 750 teeth)

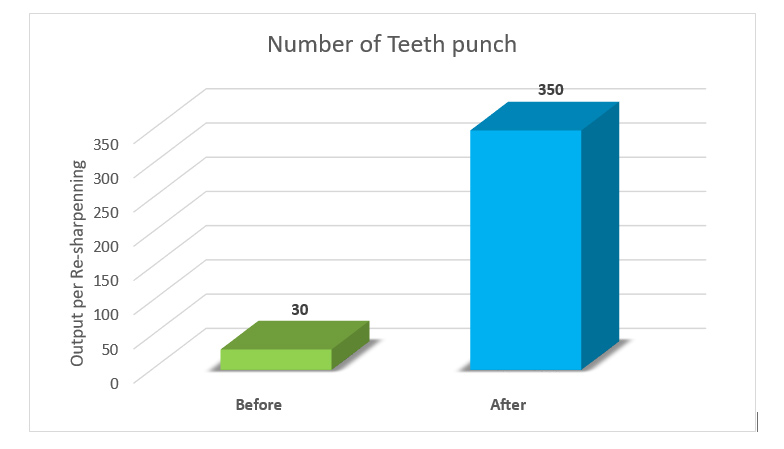

- Very low & unpredictable tool life (30 – 40 teeth) frequent tool sharpening required.