Productivity improvement in “Inline Fuel Injection Pump” value stream to ensure product profitability

Company: BOSCH Limited

Project initiation date: Jun 2012

Challenge

Inline pump is Key product for Bangalore Plant and it has reached maturity stage of its life cycle. To ensure competitiveness and market share there is tremendous cost pressure on this product. Hence productivity improvement was selected as key measure.

- Higher lead time and reduced output due to crisis-cross flow of Pumps in post assembly operations (Phasing, Calibration, pre packing and Q-Screen Operations)

- Non value added activities in DV Holder Line

- Process oriented layout resulting in production failure to pump assembly, high inventory of camshaft.

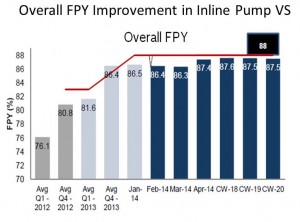

- Lower FPY in assembly and sub assembly processes across value stream

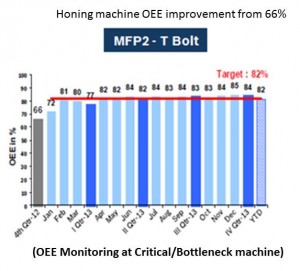

- Consistent but low OEE (Benchmarking-DS/Brumschist) of Critical/Bottleneck machine

- Low type wise delivery fulfillment to customers

- Supplier delivery performance not up to the mark

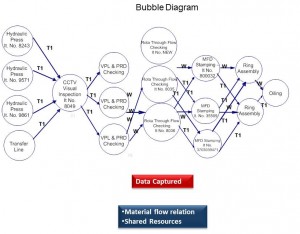

To resolve above issues we have used various quality/management tools like: Pareto analysis, Ishikawa Diagram, Bubble Diagram

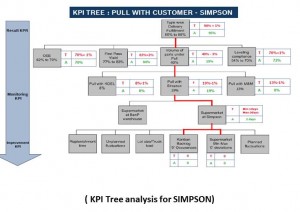

In line with our plant vision we have used Brainstorming, System CIP workshop and KPI tree methodology to identify and prioritize focus areas. It also helped us in aligning our actions with targets. KPI tree, Lean Line Design (LLD), E-Kanban and consumption based production. Brummschicht

Data Collection

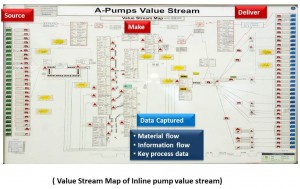

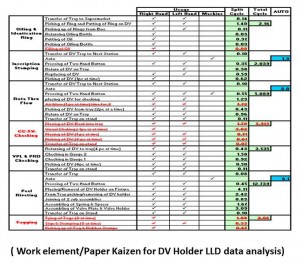

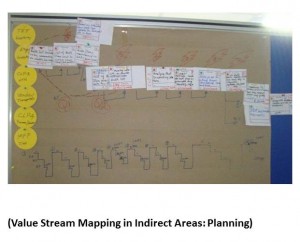

Data collection through Value Stream Mapping and Bubble Diagram for Assembly line integration and LLD in DV holder.

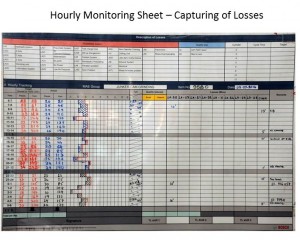

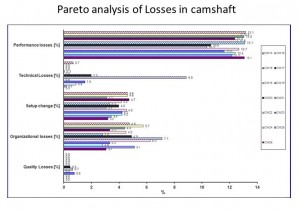

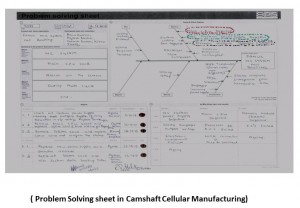

Production data and losses were collected through hourly Monitoring sheet. Pareto chart was used identifying top losses. (in Camshaft Grinding and T- bolt Honing M/c)

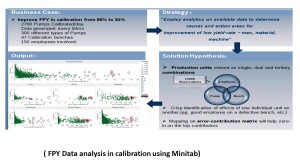

(Autocal data collection for FPY improvement in Calibration)

Analysis and Solution Development

MTM Analysis, Stack diagram & Operator Balance chart were used to improve material flow and operator movements in assembly line integration and LLD and Cellular manufacturing.

Application of Shainin method to analyze the major rejections in calibration and also use of “Error – Contribution Matrix” to zero in on top contributors

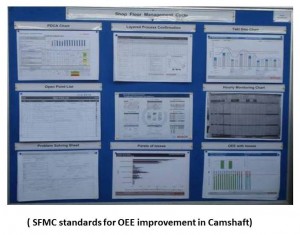

PDCA and Problem solving sheet (PSS) were used to analyze and develop solutions as a part of SFMC approach in critical and bottleneck machines.

Solution

KPI Tree approach for analyze and develop solution for improve type wise fulfillment.

Implementation

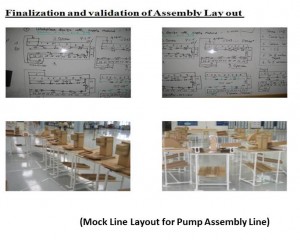

Solutions related to Line integration, LLD and Cellular Manufacturing were validated using “Mock Line Layout” Methodology. (Before-After)

Eg: DV holder - Optimization from 6 stations to 3 stations, FIFO between the stations established

Assembly line - External U line converted to internal U

Following 6 Kaizens were implemented during FPY improvement across value stream. Solutions were validated using Shainin tool paired comparison.

Eg: Modifications in design of Base cup mandrel eliminate contact between O- ring and adhesive & reduce replacement cost.

OEE improvement done through SMC approach and validated using layered process Confirmation (LPC). Eg: Technical losses reduction by optimization of spindle parameters in honing m/c and honing stone specifications.

Sustain

Yes,

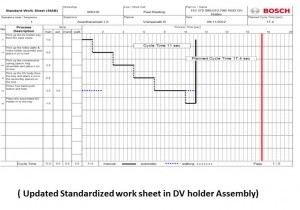

Layout, Work instruction chart and Standardized Worksheet for

Operators,updated based on improvements done in camshaft and calibration

area.Updation of documents like drawing, Control Plan, FMEA etc. done in

Pump Assembly and DV Holder assembly Line

Benefits

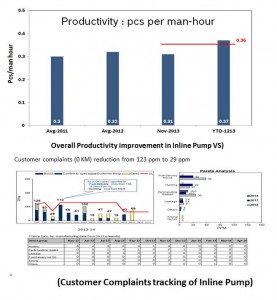

Overall Productivity increase from 0.3 to 0.37 pcs/man-hour by line Integration and lean line design

Financial benefits

Direct Cost Saving = 46.1 mINR/annum

Avoidance of Investments= 27.5 mINR D

V Holder: 2.5 mINR

Honing machine: 25.0 mINR

Production

- a) 2012: 7,40,177 Pumps

- b) 2013: 8,06,381 Pumps

- c) Additional business: Export market 16,000 pumps/annum d) Rationalization of Manpower

Horizontal deployment

Considering Lessons learnt from successful Implementation of Line Integration and LLD; Horizontal deployment extended in Flyweight and Gov. cover subassembly Value Streams. OEE and FPY improvement projects are also initiated in rest of the processes/VS

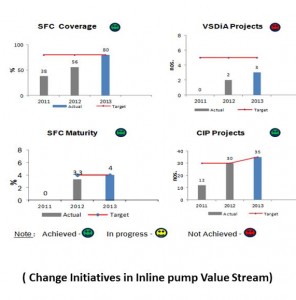

Success stories have been shared with other VS and cross-functional teams through weekly Continuous Improvement Process (CIP) and Shop Floor CIP (SFC) Presentations.

Achievements have been shared and awards received at many industry platforms like NCQC, CCQC, QCFI and NIQR .

Other inputs

Many lean initiatives have also been implemented in indirect areas through VSDiA (Value Stream Design in Indirect Areas).

Below mentioned change initiatives has also helped the value stream to progress in the direction of achieving our plant Vision