UCAL

Brief description of the project.

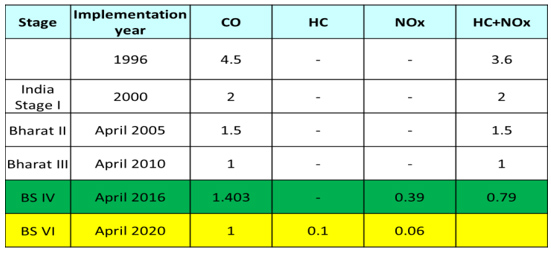

To improve the competitiveness of the business in a changing BS-IV to BSVI regulation on Two wheeler & Four wheeler business, through

- Innovative cost effective alternate product design to FI (Fuel Injection System).

- To completely reengineering process from procurement to delivery.

- To inculcate set of new work ethos in the plant

- To adapt World Class Manufacturing Methodologies

Product

Innovative, Creative e-carburetor patented and approved from ARAI and customer

- Quality function deployment (QFD )

- Multiple Environment Over Stress Testing (MEOST)

- Short- Term & Long- Term Endurance Test

- Reliability Engineering

- Customer field proving and approval

Process

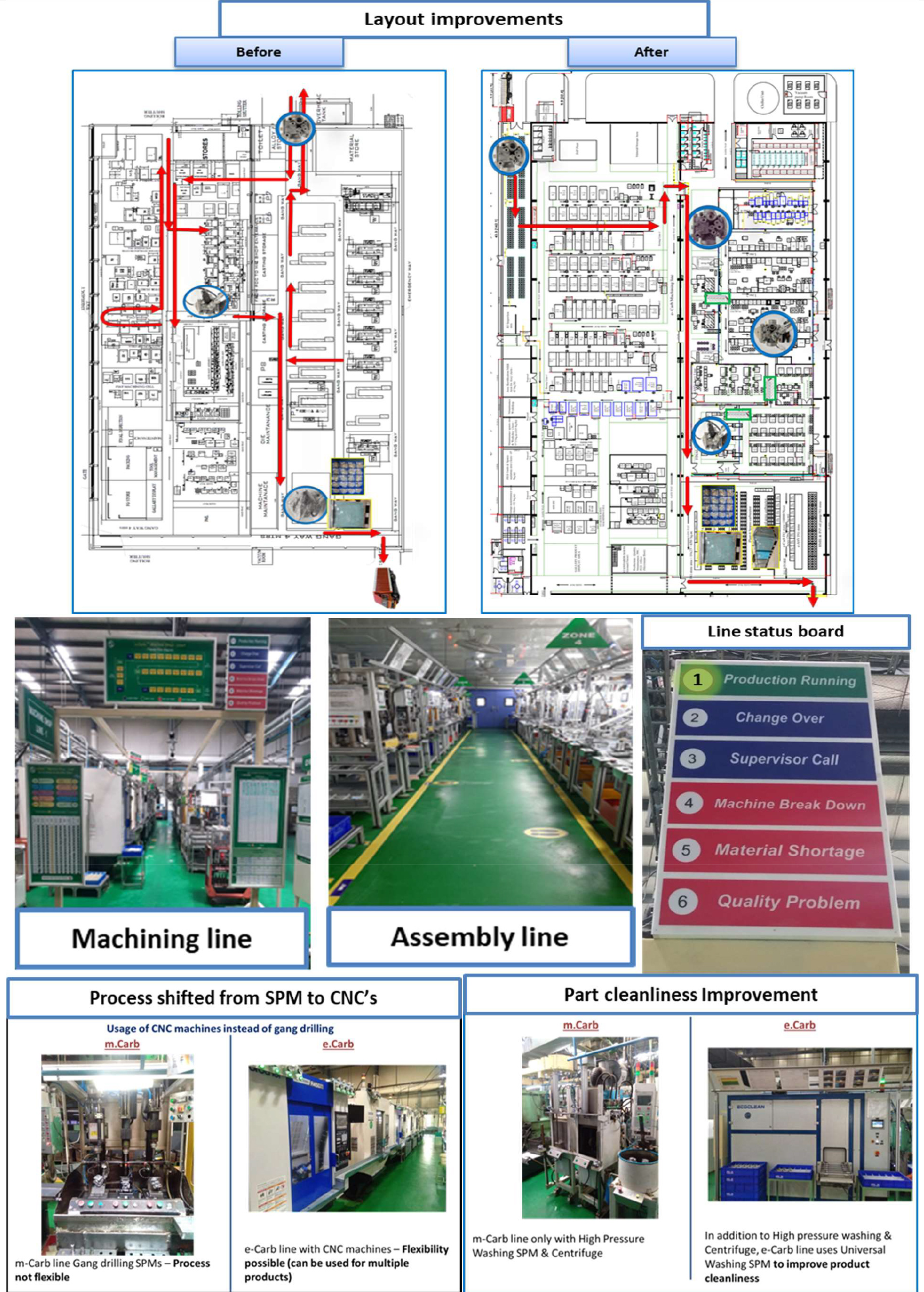

Through technology mapping and adaptation of World Class Manufacturing Methodology.

- Quality function deployment (QFD)

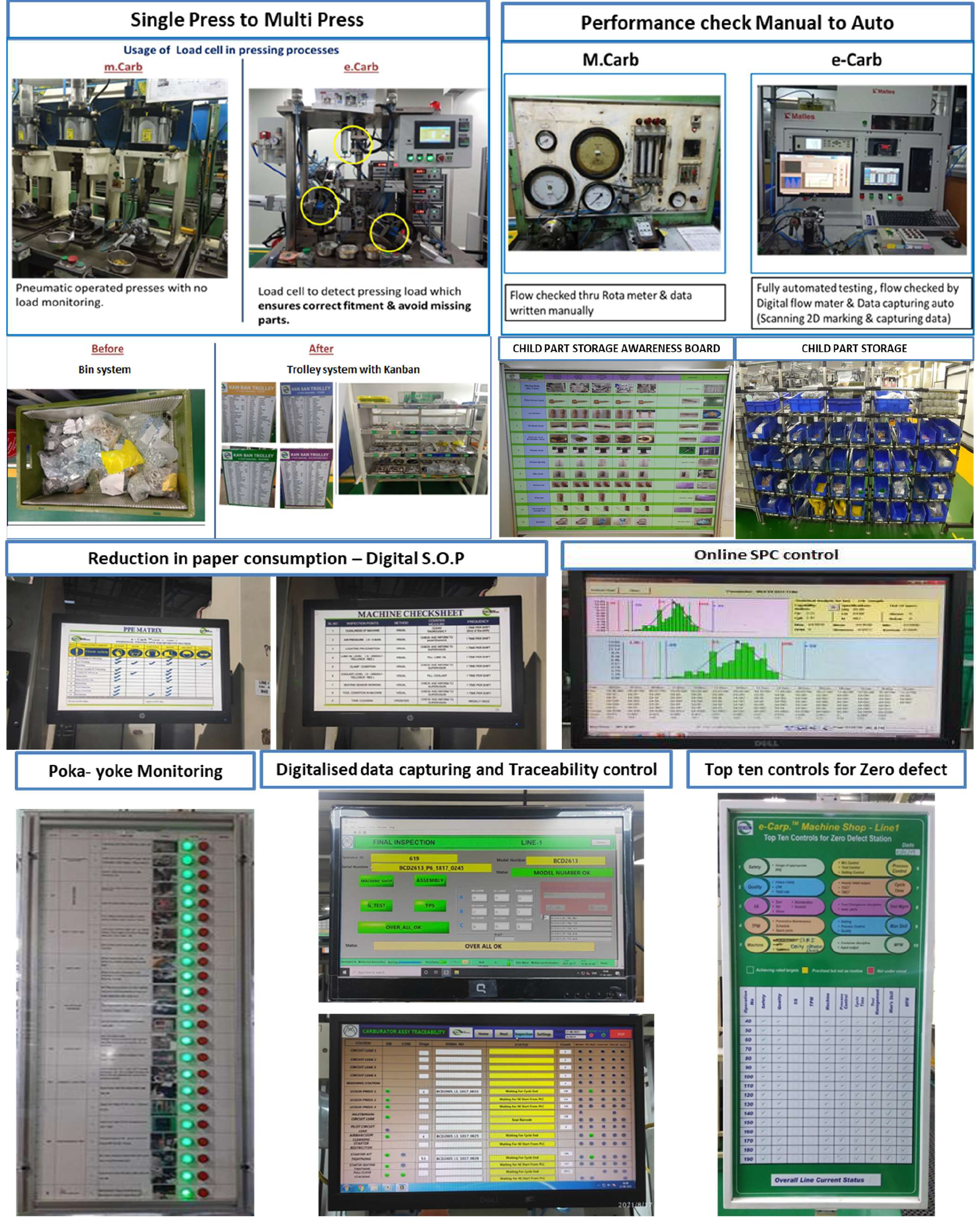

- Single Piece Flow

- Multi Machine Manning

- Built in Poka Yoke

- TPM Basics and Jishu Hozen

- Quality Planning, QA Matrix

- Online Quality Control

- Computer Aided SOP

- Levelled Production and Inventory Management Through KANBAN

- Visual Management/ DRM

- Continuous Improvements (kaizen)

People

- Build zero defect product - Operator responsibility for built in Quality

- Skill building – OJT, OFJT

- Total employee involvement

Trigger for the project - To compete with FI Technology in cost effective manner meeting adequately BS-VI norms

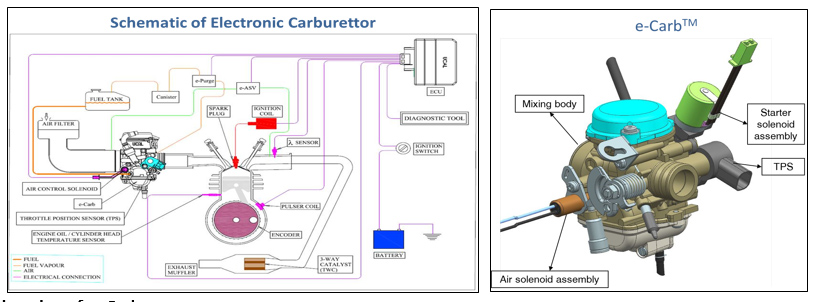

Brief explanation of e- Carburetor:

Carburetor having four main circuits,

- Inlet Circuit

- Pilot circuit

- Main circuit

- Starter circuit

This four circuits control the fuel consumption and life of the vehicle.

Main parts of e-Carburetor & Its function :

Mixing body: It is used to connect between engine and fuel tank. Fuel and Air passing through mixing body circuits to control the ratio to meet vehicle speed and emission requirements.

Mixing body: It is used to connect between engine and fuel tank. Fuel and Air passing through mixing body circuits to control the ratio to meet vehicle speed and emission requirements. Main jet: Passage of fuel from the carburetor. Main jet is an important part in vehicle while we are driving at higher speed.

Main jet: Passage of fuel from the carburetor. Main jet is an important part in vehicle while we are driving at higher speed.- Pilot jet: Passage of fuel from the carburetor. Important contribution part for lower speed and idle vehicle condition.

- Air solenoid assembly: Solenoid is incorporated in the main air circuit and pilot air circuit to control the air fuel ratio. Air fuel ratio is maintained at the required level with the help of ECU.

- Starter solenoid assembly: Solenoid is incorporated in the starter circuit to control the air fuel ratio. Air fuel ratio is maintained at the required level with the help of ECU.

- TPS (Throttle Position Sensor): For throttle opening with variation ignition time. % of throttle valve opening.

Advantages of e-Carb from M-Carb and Competitive with Fuel injection system:

- BS-IV norms requirements - M-carb

- BS-VI norms requirements - e-Carb

- e-Carb meet BS-VI norms competetive with Fuel injection system

- FI systems cost is 30% higher than e-Carb system.

- Easily servicable compared to FI system Since,Carburetor is used for a very long period of time so knowledge about carburetor is user friendly.

- Additional electronic sensors used in FI, so its very complicated for servicing comparing to carburetor.

Solution generation, Innovation and Complexity.

- In current scenario the price of FI system per product is very high which will increase the price of two wheelers in Indian market. In order to overcome this we need an alternate product.

- In collaboration with Bajaj R&D and Our R&D team came up with an Idea of developing modified carburetor from the existing model with addition of electronics components like solenoids & innovated a new product (e- Carburetor).

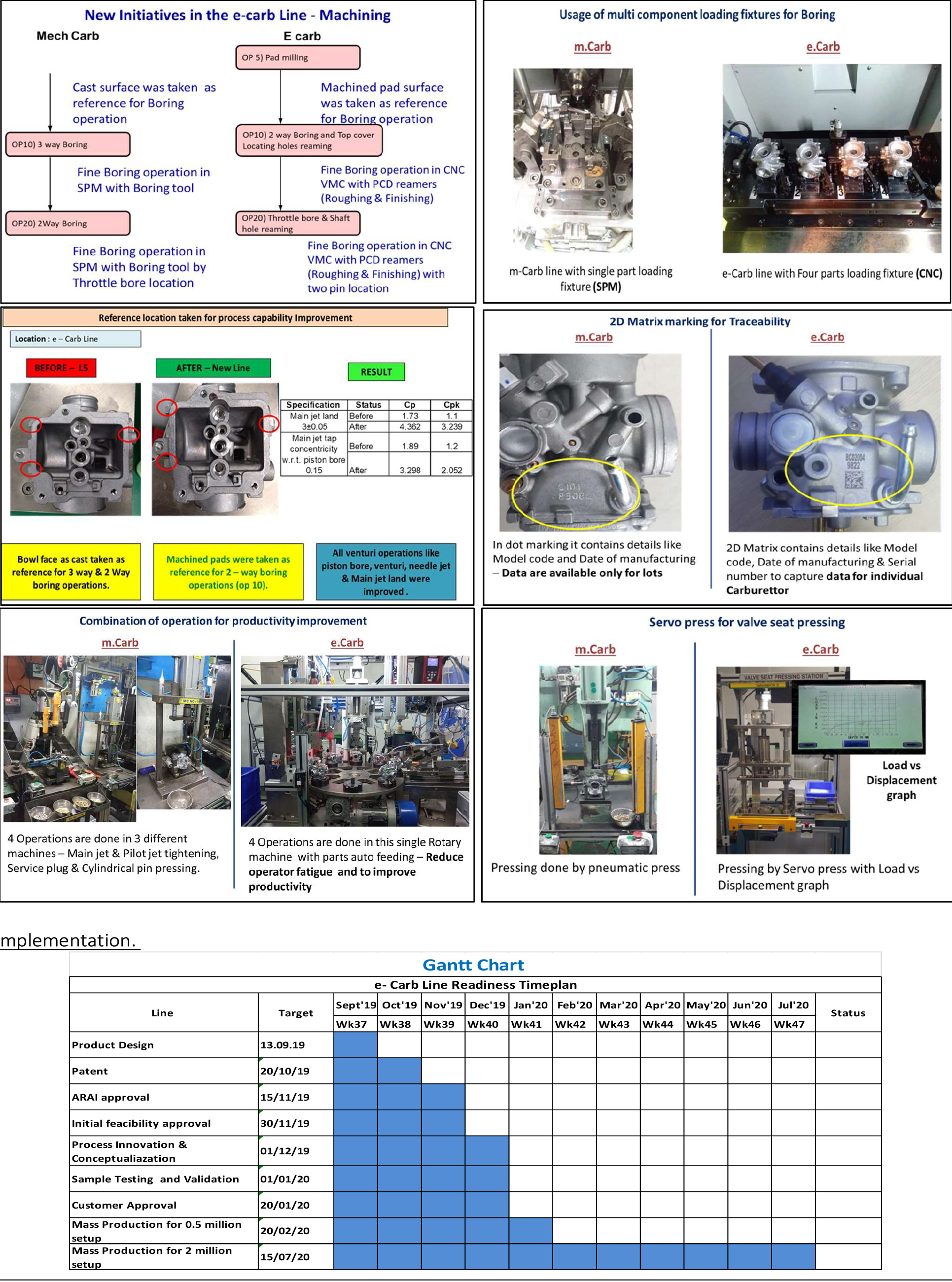

- To transform our manufacturing setup from Traditional to ‘state of the art’ Technology e-carburetor.Machining

- From individual Drilling (SPM) stations to CNC (Multi Operation) - To improve process capability

- Multi loading setup to Single loading setup – Productivity with wrong loading prevention

- Cutting Tools - Carbide cutting tools to PCD tools – Tool life improvement and accuracy

- Manual checking to Online dimension checking – To avoid manual error

- Machine interlock - To avoid defects passing through to next stage

Assembly

- Part traceability and Online data capturing with barcode

- Multi Station Operations (Rotary) – To improve productivity

- Auto feeding setup for child parts (e.g., Ball, Plug, Jets) – To improve productivity and avoid manual error

- Machine interlocks – To avoid defects passing through to next stage

- Poka- Yoke – To avoid wrong loading, double part missing operation (Preventive Poka- yoke)

- Tightening and torque with feedback setup – To avoid customer complaints

- Manual judgment in carburetor performance (G-Test) to Auto Judgment – Consistency in quality

- Packing setup – From cotton box to reusable pallets –Environment/ Cost reduction

- All stations ok part verification before packing – To avoid customer complaints

Results / Impact.

| DESCRIPTION | UOM | BEFORE (2019-2020) |

AFTER (2020-2021) |

% CHANGE |

| Sales (M-Carb) (e-Carb) |

(In crores) | 97 13 |

9.6 202 |

90 1453 |

| Sales Per Employee / Annum | In Lakhs | 20 | 31 | 55 |

| Value Added For Employee | Ratio | 2 | 4.67 | 133.5 |

| Profitability - Gross Margin Percentage | In % | 13.2 | 27.5 | 108.3 |

| Labour Cost | In % | 12.15 | 7.36 | 39.4 |

| Maintenance (Power Cost ) | In % | 3.86 | 1.64 | 57.5 |

| Material Cost | In % | 58.8 | 57.6 | 2.0 |

| Poor Quality Cost | In % | 1.92 | 0.9 | 53.1 |

| Kaizens | Nos | 487 | 682 | 40.0 |

| Customer Line Rejections | PPM | 210 | 63 | 70.0 |

| Field Failures | PPM | 1077 | 426 | 60.4 |

Resource impact.

| Parameters: | Before | After | Unit of Measurement |

| Energy Consumption | 35.13 | 30.64 | In Lakhs |

| Raw Water/ Day | 79800 | 75600 | In kilo ltrs |

| Coolant Consumption | 0.42 | 0.37 | In % |

| Space savings -2700 Sq. meter and utilised for Assembly & Spare warehouse | 5400 | 2700 | In square meter |

Business metrics.

| # | Parameters: | Before | After | Unit of Measurement |

| 1 | Market share with Bajaj - For this new product | 20 | % | |

| 2 | Sales by Value | 97 | 202 | Value In crores |

| 3 | Sales by volume M- Carb |

2.4 | 1.2 | Nos in Lakhs |

| 4 | e-Carb | 1.0 | 11.0 | Nos in Lakhs |

| 5 | Competitive market position (e-carb) | 2nd | 1st | - |

| 6 | Internal service level adherence | 95 | 100 | % |

| 7 | Customer satisfaction ratings | 72 | 94 | % |