Godrej & Boyce Mfg. Co. Ltd.

1. Brief Description of the project :

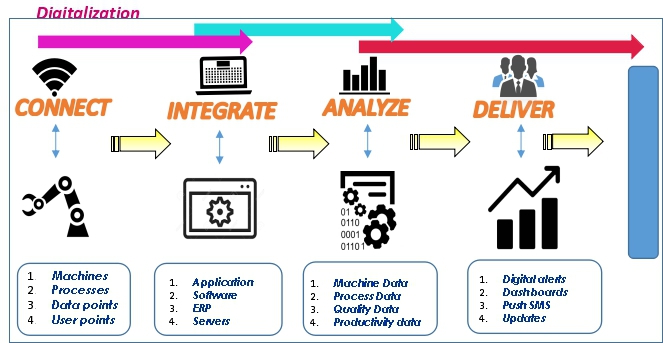

This project is about use of digitalization in manufacturing processes for aligning our self with 4th industrial revolution. In our manufacturing processes huge quantum of data is being generated. Capturing of huge quantum of data, analysis of data and decision making based on analysis was a tough task. A need arises for a platform where we can capture real time & accurate data which can be analyzed quickly, and fast decisions can be taken for improving resource utilization & reducing operating cost.

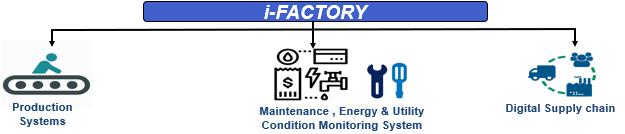

We have divided our scope of digitalization in 3 main areas : production system, energy & utility monitoring system and Digital supply chain on the path to make our factory -i factory.

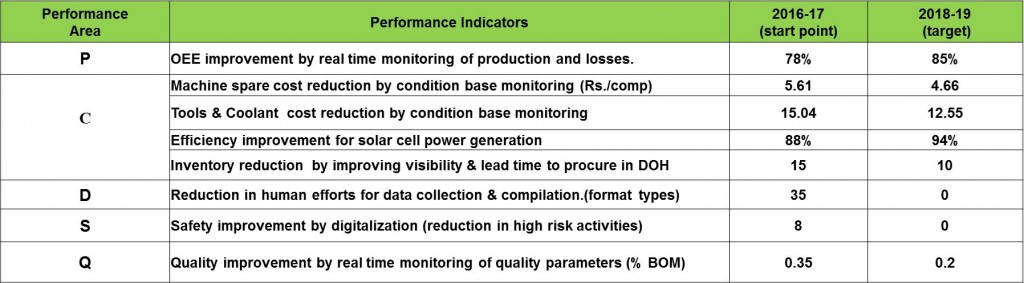

We have clearly defined parameters where we want to improve with the help of digitalization. Below are the targets

2. What made your company to take up this Project? Describe briefly :

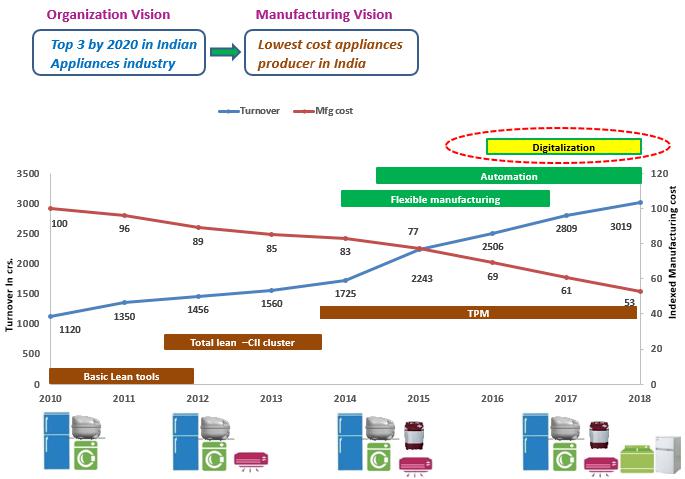

Godrej & Boyce Mfg. Co Ltd. Is the only Indian appliances manufacturing company competing with international brands in a fiercely competitive market. We have set the vision of being amongst Top 3 by 2020 in Indian Appliances industry. To realize this vision, Manufacturing function has set the vision of becoming Lowest cost appliances producer in India by practicing manufacturing excellence tools.

Below trend shows the evolution of manufacturing processes & systems over last few years which is helping us in realizing our vision. In phase 1 We started with Basic lean tools like 5-S, line balancing etc. for improving production processes. In phase 2 we have done total lean management through CII industry cluster to facilitate total mind set change. In next phase we have implemented TPM for improving plant efficiency. We have achieved good results with all these initiatives.

But we understood that for competing with international brands we need Improvement across the entire value chain & prepare our self for the future.

For that we have started practicing industry 4.0 & Digitalization.

3. How did you generate the solution which you implemented?

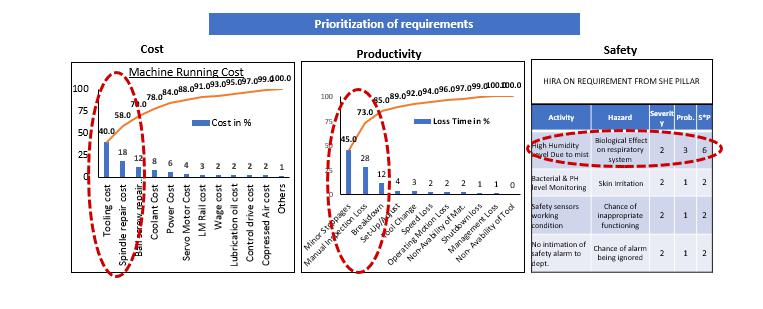

We conducted the brainstorming session with in our team for improving resource utilization, reducing conversion cost and safety improvement for realizing our vision of lowest cost appliances producer in India. Team came out with 76 ideas for implementation. Implementing all 76 ideas required huge investment. So, we prioritized that ideas based on contribution for cost, productivity and safety.

Based on the pareto chart we shortlisted the option of :

Based on the pareto chart we shortlisted the option of :

- Optimized tool life by condition base replacement of tool.

- Reduction in in spare cost by condition base replacement of spare parts.

- OEE improvement by capturing and elimination of stoppages.

- OEE improvement by reducing manual inspection time

- Safety improvement by real time monitoring of health of mist collector filters.

From the last few years we were continuously working for improvement of above mentioned parameters with the conventional manual methods and achieved satisfactory results. To improve it further, different approach was required where we can capture real time and accurate data at micro level, which can be analyzed quickly, and fast decision can be taken. This was only possible through digitalization. We decided to introduce digitalization.

4. Describe how the selected solution was implemented.

We have devised and used our 7 steps methodology for implementing digitalization.

Step - 1 : Need Identification: we have clearly identified below mentioned needs based on the pareto charts.

- Optimized tool life by condition base replacement of tool.

- Reduction in in spare cost by condition base replacement of spare parts.

- OEE improvement by capturing and elimination of stoppages.

- OEE improvement by reducing manual inspection time

- Safety improvement by real time monitoring of health of mist collector filters.

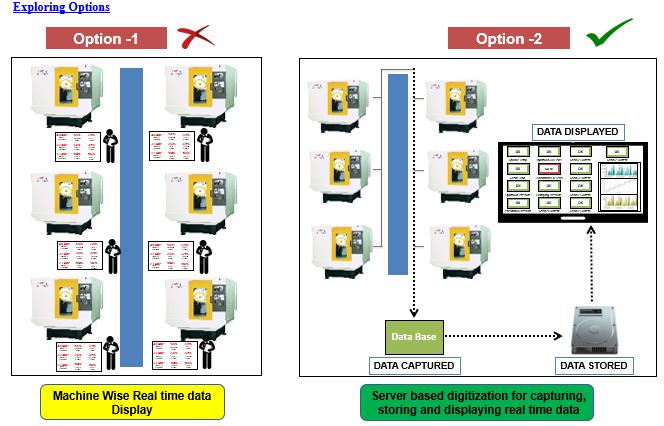

Step - 2 : Exploring Options: We have explored 2 options

Displaying of all above data for all individual machines.

Server based digitization where data can be capture, store and display real time data

We have selected option 2 because stored data can be used for making machine history charts for future references.

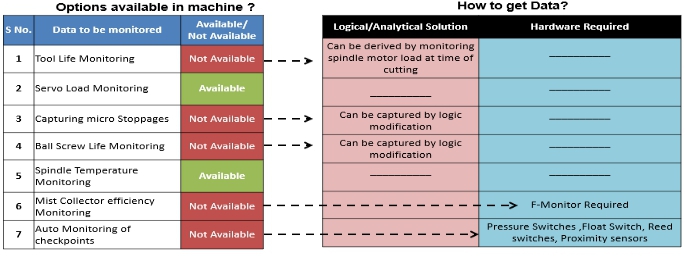

Step - 3 : Feasibility Study: We did feasibility study to check possibility of capturing these data real-time for above 7 parameters? We observed that out of 7- 2 parameters can be directly monitored from machine for 3 parameters we need software modification and these 2 data’s can be monitored by additional sensors.it means real time data monitoring for all these 7 parameters is feasible

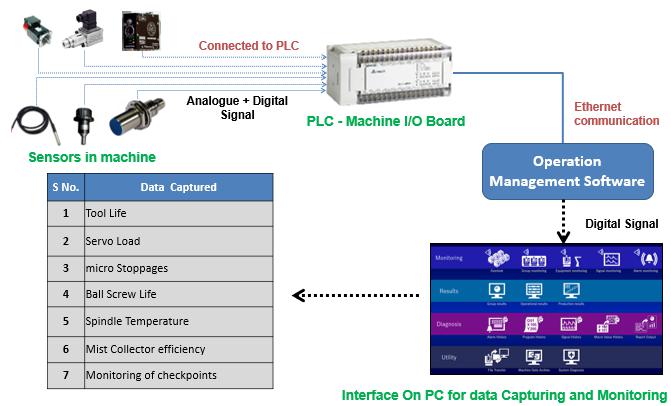

Step - 4 : Designed concept: After Feasibility study we designed the working concept for real time data capturing. Here Data will go from all machine sensors to PLC. From PLC data will go to Operating software with help of ethernet communication and analog signal will be converted to digital. For interface we selected software MT link I where data can be captured after every 0.5 second and considering future needs up to 50 machines can be integrated. By help of this interface, data will be displayed on the screen.

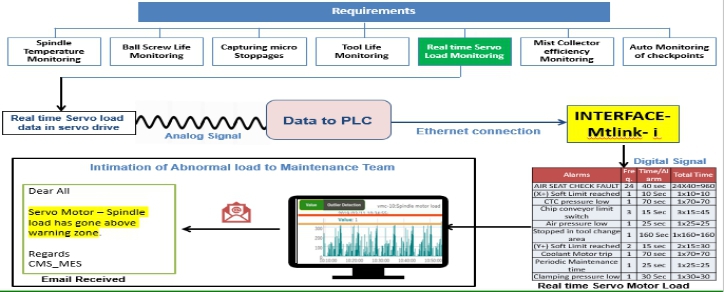

Step - 5 : prototype and testing: To validate the design concept, we selected real time servo load monitoring for prototyping. Actual Load data of servo motor moved to motor drive, from motor drive to PLC and PLC to MT link I interface by ethernet. We captured servo motor load from machine after every 0.5 second.

Step - 6 : Installation and implementation: After successfully completing the prototype for real time servomotor load monitoring, same methodology was used for real time monitoring of Minor stoppages, real time monitoring of spindle load, current and tool condition, real time monitoring of inspection points etc.

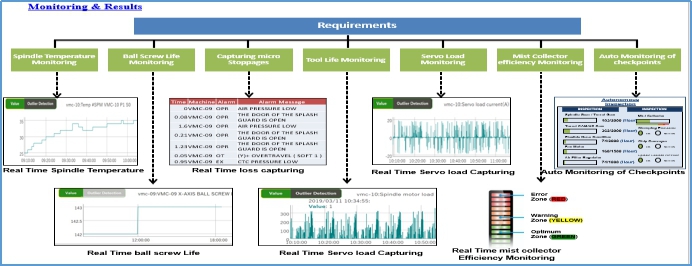

Step - 7 : Monitoring results: These are the results of digitalization, we have started real time monitoring of spindle temp, Capturing micro stoppages, Real time tool life monitoring, Real time servo load monitoring etc.

How to utilize Real time recorded data for-

- Operational cost reduction

- Enhance Resource utilization

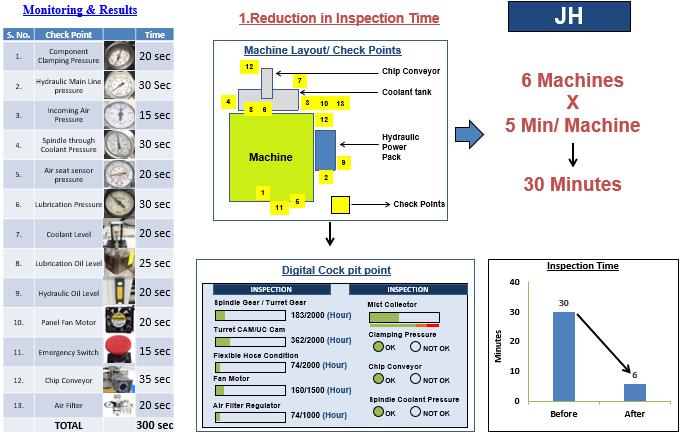

Case Study - 1 : Reduction in machine inspection time with the use of digital Cockpit (digitalization).

For maintain the machine operator used to check 13 manual check points around the machine. It was taking about 5 minutes. Here operator was operating 6 machines. Every day there was production loss of 30 minutes due to operator not available due manual inspection time for 6 machines which he operates. Now we have introduced digital cockpit point where he checks all the critical machine points at a single glance. Inspection time reduced from 30 minutes/shift to 6 minutes.

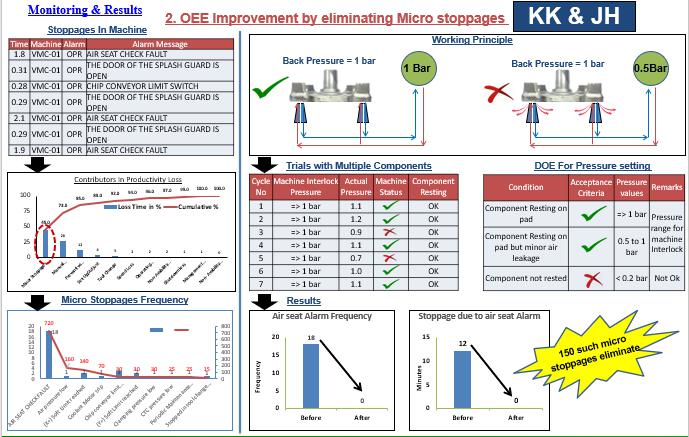

Case Study - 2 : OEE improvement by elimination of minor stoppages with the use of digitalization.

This case study is about real time capturing of minor stoppages. When we captured minor stoppages real time it came as a very big surprise that 44% of OEE loss was due to minor stoppages. On further analysis it came out that minor stoppages which are less than 1 minute and repetitive in nature operator will not able to record it manually. Here digitalization helped. Machine stoppage due to Air seat pressure low was the major contributor for the production loss and not recorded because when this alarm comes, operator just de-clamp the part and clamp it again and start the production.it was because of air leakage form the component and resting pad due to uneven surface of casting. Machine logic was such that when back pressure on the gauge will be more than 1 bar then only machine will start. but in a shift machine was giving these types of false alarms as pressure drop to less than 1 bar and cycle stops because of uneven casting surface despite component placed on the fixture correctly. Real time stoppage data captured indicated that, this as an improvement project. With the DOE tool we set the machine interlock to 0.5 bar rather than 1 bar. We eliminated this stoppage fully from the machine. We saved 12 minutes/shift production loss with the help of real time data capturing which triggered this improvement. Below is the sequence of operations showing this improvement. About 150 such stoppages identified and eliminated in the plant.

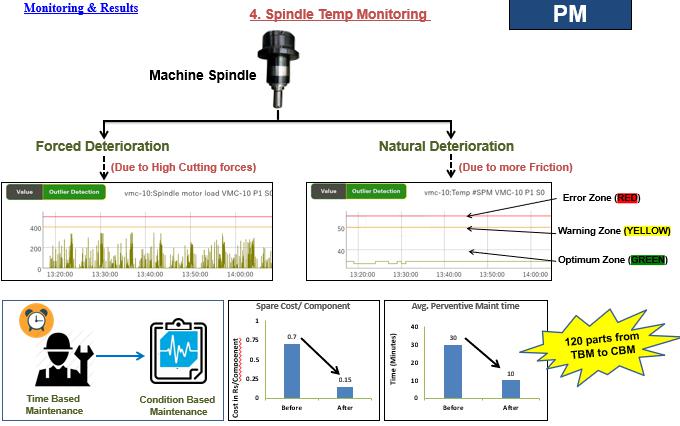

Case Study - 3 : Spare cost reduction by real time monitoring of health of critical machine spares.

With the help of digitalization, we started monitoring real time health of the machine’s critical elements like temperature of the servomotor, spindle etc. Also, we started monitoring of load on the spindle and motors while machine Is running, and metal cutting is happening. We have set the 3 zones for monitoring critical spares.

Zone 1 (optimum zone)- When load will be in this zone it will indicate everything is normal for the spindle.

Zone 2 (warning zone)-When load will reach to this zone system will through warning mail. By taking timely action we can prevent the part before failing.

Zone 3 (Error Zone)-After warning zone if there is no action then load will reach to error zone. Here software will not allow machine to run unless rectified. With such type of digitalization, we reduced spare and maintenance cost by 68%. We have implemented such improvement on 120 parts where we are replacing the parts based on condition rather than time.

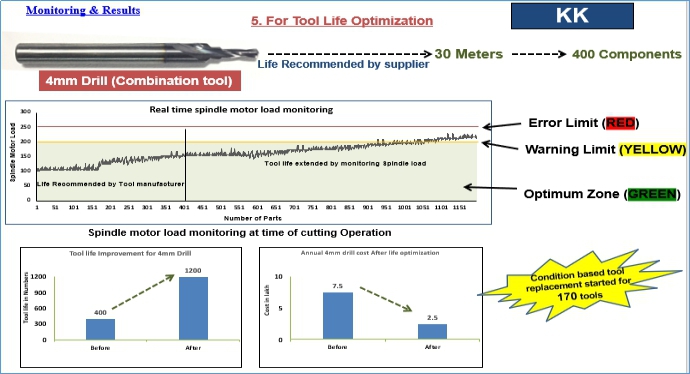

Case study - 4 : Tool life optimization with the help of digitalization.

Real time spindle load monitoring triggered this improvement. we checked the condition of cutting tool by monitoring the spindle load. This example is about the life of a solid carbide drill. Tool manufacture recommended life of this drill 30 meter but when we measure the load of the spindle when tool was cutting we observed that instead of 30 meters tool is running in optimum load zone till 90 meters. With the help of digitalization we can monitor the life of the tool by setting the load for 3 different zones and can take optimum life. This improvement reduced the consumption cost of this tool from 7.5 lakh/year to 2.5lakhs/year. Similar concept applied on 170 cutting tools.

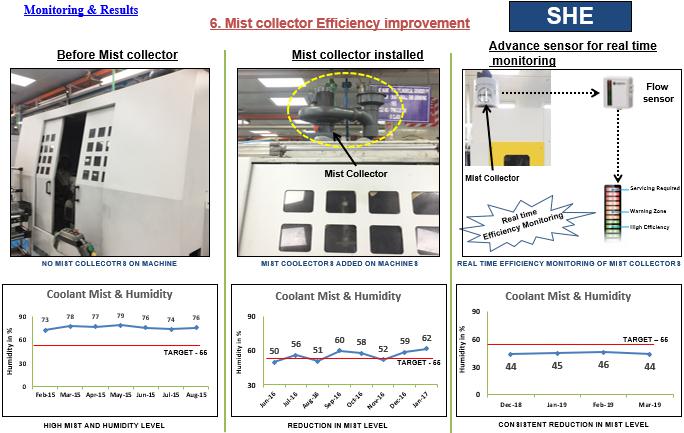

Case study - 5 : Safety Health and Environment improvement with the use of digitalization.

This case study is about use of digitalization for maintain coolant mist level and humidity in VMC section. Here we have installed advance sensor which keeps the check on health of mist collector and define the filter cleaning time. Earlier condition in the room was not maintained because of manual trigger for preventive maintenance of mist collector. Now this sensor measures the pressure on the filter. If indication reaches to red zone on the filter, then it triggers for filter cleaning.

5. Value Creation and Business Results:

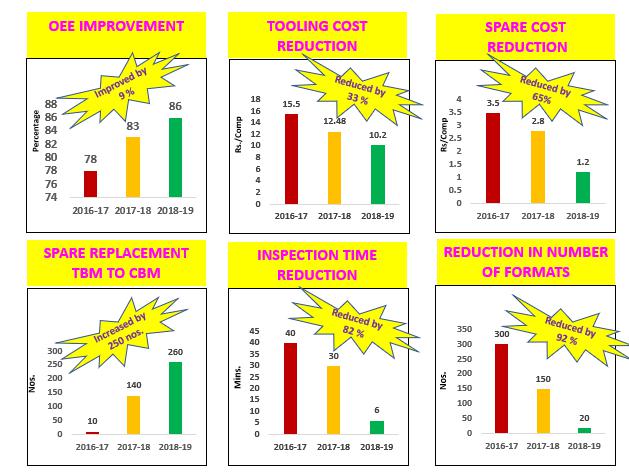

Below are the results we achieved after successful use of digitalization in compressor machine shop which was the biggest cost center for compressor manufacturing.

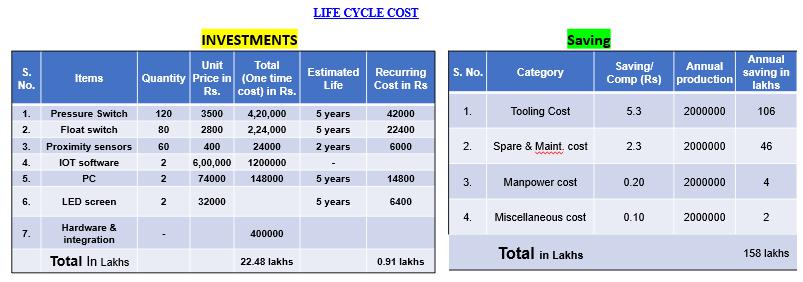

Tangible benefits and ROI: One-time investment for this project is 22.48 lakhs and recurring cost is 91 thousand /annum. Saving from this project is 1.58 crores/annum. Payback for this project is approx.3 months

6. Environmental considerations: (if any):

- With the introduction of digitalization, we have eliminated use of paper in the form of hard copies for data capturing like production monitoring calculation sheets, machine check sheets and history sheets etc. Total annual 3600 paper saving by eliminating hard copies.

- We have also used digitalization for improving environment condition by reducing coolant mist level in the plant by real time monitoring of mist collector health.

- We have used digitization for improving efficiency of solar power generation system. By taking quick action solar cell power generation is increased by 8% which is increasing our share of green energy.

7. Can the ideas, principles, concepts or techniques developed by you be implemented in other areas in your company and in similar / other industry?

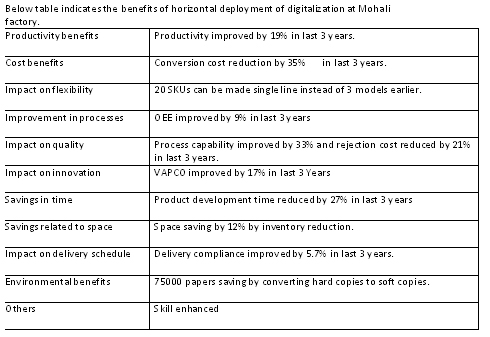

Yes, we have horizontally deployed digitalization in the areas of Supply chain, Energy and utility condition monitoring system & maintenance system. We have horizontally deployed the learning in other product category lines like refrigerator, washing machine and Air condition etc. along with other manufacturing location at Shirwal Maharashtra.

Our organization is private owned business, so all the improvements mentioned in % term.

Our organization is private owned business, so all the improvements mentioned in % term.

8. Give any other information that supplements your project / case study to be a winning entry.

After such encouraging results, it is imperative for us that we must continue our efforts to strive towards industry 4.0 and digitalization for sustained and continual improvement. In line with this, below is our Digital factory road map. We have envisaged a digital enterprise extending to all 4MTE domains and we are looking forward to digitalizing our entire value chain by end of Financial Year 2021.